New Question...?

Garry,

I assume materials calibration and metallurgical testing are a part of your services? Here's a scenario and a question for you (or anyone else of course):

Back in 1998 I was working for UK firm over in Singapore as Senior Technical Advisor. We had a shopping mall project which required formwork support through the atrium to the underside of the roof which housed an outdoor swimming pool. Obviously this was quite a heavy duty design due to the water loading (live load). The concrete beams to be poured were 8m x 2m x 2m and Cuplok (steel) support was used.

The design was perfect and passed by a Government approved Chartered Engineer (a requirement out there). When the project commenced, there was the usual site arguments of the contractor not wanting to follow the designed drawings etc. I have lost count of how many Inspections I had failed. One particular night in question, after yet another failed inspection, the contractor proceeded to pour concrete without authorization from myself or the Project Engineer.

The formwork had failed because it was incomplete and they refused to install the last 3 lifts of bracing. The inevitable happened and there was a collapse as predicted by myself (Christ how I hate being right about things like that!), unfortunately killing 9 personnel. Senior persons were charged with manslaughter and went to prison and so may they rot there for eternity!

Now, owing to the lack of bracing the obviously legs began to bow and live load being live load, will always search for the weakest point, in the case of Cuplok, it's the blade end on the ledger or transom that goes first. The structure split into two sections and quite literally tore in half before imploding on itself.

Don't worry, I am getting there......

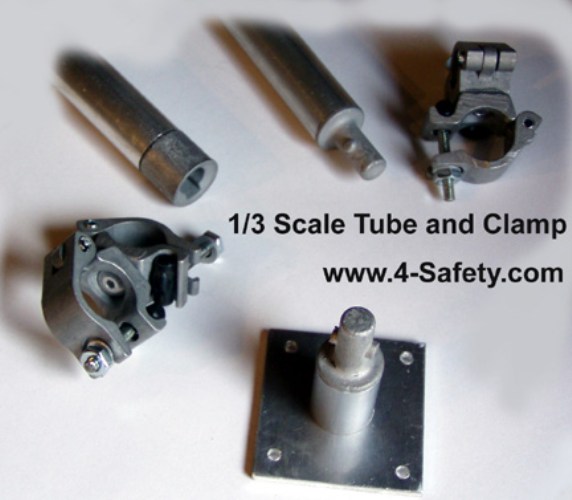

I would assume that during the manufacture of Cuplok, Layher, Kwikstage and even Readylok transoms there must be MPI performed to test the welds. In this case, all our Cuplok was manufactured under the watchful eye of a BS Inspector in the UAE. We had all the metallurgical data and test certificates etc, which is also a requirement by Singaporean law when importing materials into the country.

Now then my question, eventually: Although MPI and welding inspection is carried out at the time of manufacture, are random tests carried out for materials that are out in the field and have been in service for many years? It's a concern of mine that companies are using modular/system scaffold materials as old as 15 years (maybe even longer?). Surely over the years of stress on the joints, there has to be some percentage of loss of intergrity, yet the calculations being applied do not reduce over the years? I do know for a fact that some Design Engineers get their calculations from the data sheets which are based on new materials!

Your thoughts please mate...?

Cheers,

Phil.