Flynn Design Solutions

Well-known member

- Joined

- Mar 9, 2010

- Messages

- 419

- Reaction score

- 0

flynnanddawson,

I have had a look at the thread and yes it looks like a very good piece of kit but I have a few questions if I may.

1, does the safelinx come in different sizes in length.

2, can it be used on a flush finished board level on birdcage scaffolds say 20 boards wide.

3, what is the safety factor on wind speed for the uplift as there does not appear to be no support ties to the centre of the boards which we will still need to tied down for the risk of the board may bow in the middle and uplift in strong winds we have to design the scaffolds on the bridges to withstand a wind speed of 120mph.

But still a very handy piece of kit for straight independents.

To answer your questions,

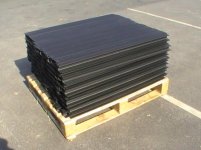

1) Safelinx is availiable in any length you require (dependant on order volume) We produce in a 5 board and 4 board as standard but are sorting out stocks to suit most common board gauges.

2) If you wanted a neat secure birdcage platform I can think of no better way than Safelinx, cable tie the units to each other through the holes and around the neaest ledger/tranny. Or stock up on 4.5 meter Safelinx. On the longer lengths there will be additional securing points arranged to provide maximum retention.

3) For serious wind environments a combination of Safelinx and board clamps may be required, although we have calculated the bow on a 13' board would have to be 260mm before it would come out of our unit, we have test results that top out at aprox 3.3kn.

Hope this answers your questions.